Standard Configuration

◎Roughness Tester Host DR16 ◎Standard Sensor

◎Multi-groove standard specimen ◎Adjustable bracket

◎Power Adaptor ◎Software

Surface Roughness tester DR.16 in UAE

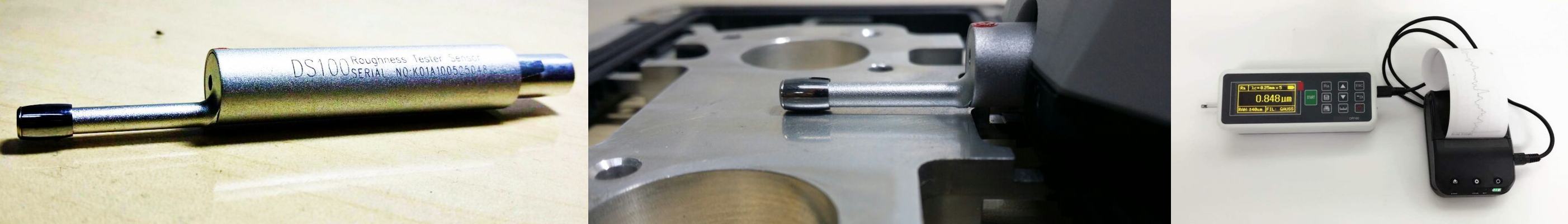

Precision roughness tester DR16 is a high precision instrument testing the surface degree of finish, and can measure surface roughness of the machined parts, including plane, bevel, outer cylindrical, surface, holes, trenches and axles and so on.

Features

◎Mechatronics design, with small volume, light weight and convenient use.

◎Use DSP chip to control and process data, with high speed and low power consumption

◎Compatible with ISO, DIN, ANSI, JIS multiple national standards

◎Continuous working time more than 20 hours

◎Large-capacity data storage, can store 100 groups of raw data and waveform.

◎Real-time clock setting and display for easy data recording and storage.

◎With automatic sleep, automatic shutdown and other power-saving features

◎Reliable circuit and software design to prevent the motor stuck.

◎Instrument can display a variety of information tips and instructions. For example Measurement result display, the menu prompts, error messages, and switches.

|

Parameter |

Indicating Range |

|

Ra, Rq |

0.005μm~16μm |

|

Rz, R3z, Ry, Rt, Rp, Rm |

0.02μm~160μm |

|

Sk |

0~100μm |

Speciality Surface Roughness Testers with our Warranty

Standard Configuration

◎Roughness Tester Host 432 ◎Multi-groove standard specimen

◎Standard Sensor ◎Adjustable bracket

◎Power Adaptor ◎Software

◎ABS waterproof case

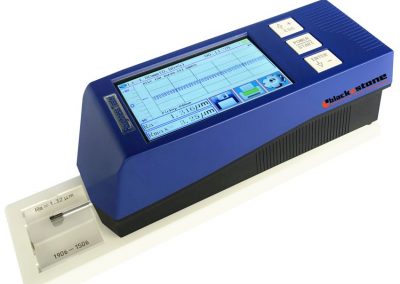

Surface Roughness tester -BS 432

Five optional sensors for measuring special shaped work-pieces.

DSP chip controlled achieves high accuracy and fast testing speed.

Matrix LCD screen displays all parameters and data.

13 parameters and 4 filtering methods: RC, PC-RC, GAUSS and D-P.

High quality with ISO/ DIN/ CE/ JIS/ FCC standards.

Memory: 100 groups of measuring data.

Power supply: 3.7V rechargeable Li-ion battery.

Standard Sensor: diamond stylus with radius 5μm, force 4mN(0.4gf), and angle 90°

Available PC software for data management and Excel reports.

Optional printer connecting by USB.

|

Model No. |

432 |

|

Roughness parameters |

Ra、Ry、Rq、Rz、Rt、RSm、RS、Rp、Rv、R3z、RSk、Rmax、Rmr |

|

Measuring range |

Ra:0.005-16μm Rz:0.02-160μm |

|

Resolution |

0.001μm |

|

Maximum driving trip |

17.5mm/0.7inch |

|

Sample length/Range (L) |

0.25mm, 0.8mm, 2.5mm/±20μm,±40μm,±80μm |

|

Evaluation length |

1.25mm, 4mm,5mm/Option from(1-5)L |

|

Filtering methods |

RC, PC-RC, GAUSS, D-P, |

|

Accuracy |

≤±8% |

|

Repeat ability |

<6% |

|

Memory |

100 Groups |

|

Operating temperature |

0 ºC -40 ºC |

|

Weight |

440g |

|

Dimensions |

119×47×65mm |

|

Standard configuration |

Main Unit,Standard sensor,Calibration block, Supporting platform, Power charger, Manual,Certificate, Warranty card, PC analysis software |

|

Optional Accessories |

Measurement Platforms , optional sensors, printer |

TOUCH SCREEN SURFACE ROUGHNESS TESTER

Model 432, Alternative to Mitutoyo surface roughness SJ-210

Standard Configuration

| Main unit | 1 | Sensor driver | 1 | ||

| Standard sensor | 1 | Cable for driver | 2 | ||

| Calibration block | 1 | Supporting platform | 1 | ||

| Height bracket | 1 | Power charger | 1 | ||

| Manual &Certificate | 1 | PC software | 1 | ||

| Parameters | Display range | Parameters | Display range |

| Ra,Rq | 0.005μm ~ 30μm | Rz,R3z,Ry,Rt,Rp,Rm | 0.02μm ~ 320μm |

| Sk | 0 ~ 100% | S,Sm | 1mm |

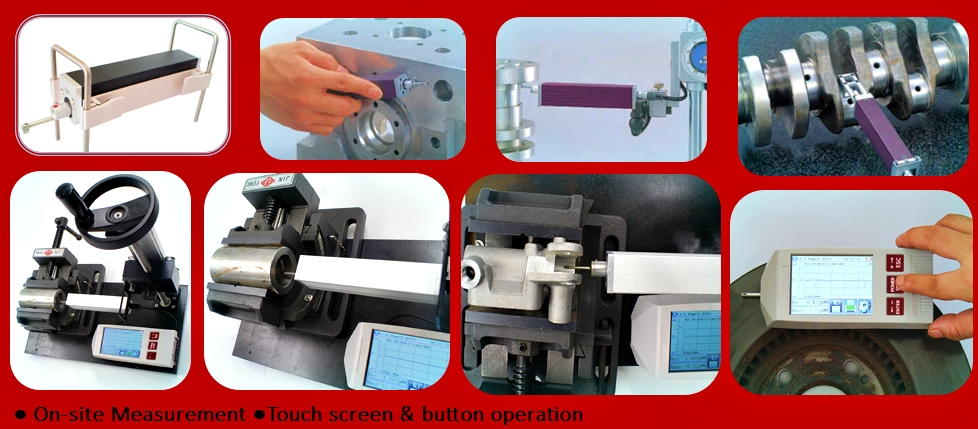

Surface Roughness tester -BS 462

● Comfortable design: Users-friendly system and intuitive menu navigation

● Measurement mode: general measuring and Splittype measuring (take off sensor) can be selected

● Multi-direction measurement such as lateral and upside

● DSP chip controlled achieves high accuracy and fast testing speed

● 3.5-inch LCD touch screen, digital and colour graphic display with backlight

● Touch screen & button operation are both available

● Rechargeable Li-ion battery allows you to make on-site measurements( > 50 hours continuously)

● Multi-functions: Bluetooth printing, Operation by APP, operate indications, Automatic sleep/shutdown

● and etc.

● Calculation results, assessed profiles, bearing and amplitude curves can be displayed

● Easy to connect with computer and printer

● It can measure the roughness of various machined parts, such as plane surface, bevel surface, outer

cylindrical surface, curved surface, small hole, groove and car axle etc.

● Application for Surface roughness measurement of metal and non-metal parts and workpiece, including

a variety of machining parts, machining manufacturing, testing, commodity inspection departments,it is

especially suitable for on-site inspection of large workpiece and production lines and the inspection,

measurement, commodity inspection and other departments of the outbound verification,no damage to

the workpiece.

| Model | 462 | |||||||

| Measuring range | 320 µm( -160μm ~ +160μm) | |||||||

| Maximum drive stroke length | 20mm (0.78 inch) | |||||||

| Resolution | 0.001μm | |||||||

| Roughness parameters | Ra,Rz,Rq,Rt,Rp,Rv,R3z,R3y,Rz(JIS),Rs,Rsk,Rsm,Rku,Rmr; Ry; Rmax,Rc,RPc,Rk,Rpk,Rvk,Mr1,Mr2 | |||||||

| Standard | ISO,ANSI,DIN,JIS | |||||||

| Graphics | Curves, roughness profile, direct profile | |||||||

| Filtering methods | RC,PC-RC,Gauss,D-P | |||||||

| Sample length (lr) | 0.25,0.8,2.5mm | |||||||

| Evaluation length(ln) | Ln= lr×n n=1~5 | |||||||

| Standard Sensor | Measuring principle | Displacement differential inductor (Inductive) | ||||||

| Stylus | Stylus Diamond,90°,5μm radius of stylus | |||||||

| Stylus force | <4mN | |||||||

| Lead head | Cemented carbide,sliding direction radius 40mm | |||||||

| Sliding speed | lr=0.25, Vt=0.135mm/s; lr=0.8, Vt=0. 5mm/s; lr=2. 5, Vt=1mm/s; Return Vt=1mm/s |

|||||||

| Indication error | ≤ ±7% | |||||||

| Indication variability | < 6% | |||||||

| Memory | 100 groups ( data and graphic) | |||||||

| Power supply | 3300mAh Rechargeable Li-ion battery | |||||||

| Dimension (mm) | Main body:64*53*160 Sensor dirver:23*27*115 | |||||||

| Weight | About 380g (Main body) | |||||||

| Operation environment | Temperature:- 20℃~40℃, Humidity:<90% RH | |||||||

| Storage/transportation environment | Temperature:- 40℃~60℃, Humidity:<90% RH | |||||||